- Home

- Products

- Industry Freezer

- Tunnel Freezer

- Impingement Belt Tunnel Freezer

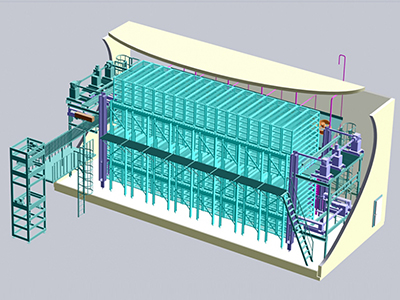

Impingement Belt Tunnel Freezer

The impingement belt tunnel freezer is primarily used to freeze flat foods, making it a popular choice in the seafood industry to quickly freeze fish fillets, shelled shrimps, squids and more. It is equipped with a highly efficient and hygienic evaporator and uses the latest liquid supply method for a heat exchange efficiency that is 20% higher than the traditional methods. Compared to traditional methods, the food weight loss is lowered by more than 1.5%.

Parameters| Items | Parameters |

| Type | CWD1200 |

| Layout Dimensions | 27000×3200×3115mm |

| Freezing product | Shrimps |

| Capacity | 1200KG/h |

| Infeed temperature | +25℃ |

| Outfeed temperature | -18℃ |

| Refrigeration consumption | 255KW |

| Refrigerant | R22 |

| Freezing time | 4-40min |

| Infeed conveyor length | 3000mm |

| Belt width | 1500mm |

| Installed power | 84KW |

Notes: These parameters are subject to change based on different products and processes.

Features- The mesh belt features a circular air duct design with a vertical symmetry in order to enhance the heat exchange effect.

- The impingement belt tunnel freezer uses an imported cold storage insulated panel production line for panel production, which ensures a high degree of energy efficiency and outstanding reliability and quality.

- The tunnel freezer is equipped with an intelligent central control system, automatic detection device and warning lights, which is easy for users to operate and maintain.

- We can design and manufacture the freezer based on different frozen food conditions and customer requirements.

- The production capacity ranges between 200kg/h to2000kg/h.

- The width of the conveyor belt ranges between 1500mm to 2000 mm.

- We make customized infeed and outfeed conveyor upon customers' requirements.

- Fully welded enclosure structure is optional.

- The CIP automatic cleaning system can be chosen to efficiently clean the inside of the freezer and reduce downtime.

- The ADF air defrost system is suitable for continuous defrosting, thus allowing the freezer to work continuously.

Founded in 1986, Square Technology Group Co. is a dedicated manufacturer engaged in the development, production, and sales of cold chain systems. We provide customers with outstanding refrigeration solutions and quick-freezing food processing systems for those handling agricultural products, seafood, baked goods, and pre-prepared foods. Through more than three decades of development, we have established long-term cooperative relationships with a number of leading food producers, including QL Group, Read Chamber, Morpol, Tyson, CP, Hormel, Cargill, Tingyi, Sunner, Zhouheiya,Juewei, and Anjoy.

Inquiry Form

Square Technology Group Co.,Ltd.

Add.: 3888 Jintong Highway, Nantong City, Jiangsu Province

Postcode: 226371

Contact: Fiona Tao, Vivi Wu

Tel.: +86-513-86615866

Fax: +86-513-86221280-8016