- Home

- Products

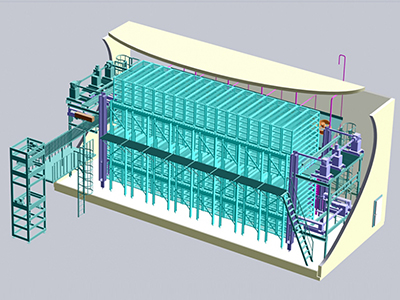

- Industry Freezer

- Tunnel Freezer

- Mesh Belt Tunnel Freezer

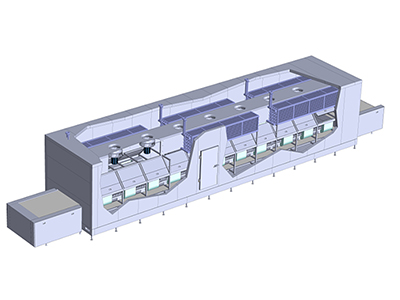

Mesh Belt Tunnel Freezer

The mesh belt tunnel freezer is used to achieve a quick freeze process for granular and small pieces of food. A larger mesh belt tunnel freezer is also applicable to individual quick freezing of prepared food, such as an entire chicken or fish. This freezer is also capable of being connected to the front or back of other customer processing lines.

Parameters| Items | Parameters |

| Type | SWD2-700 |

| Dimensions | 16000×3200×2660mm |

| Frozen products | Dumplings |

| Capacity | 700KG/h |

| Infeed temperature | +25℃ |

| Outfeed temperature | -18℃ |

| Energy consumption | 100KW |

| Refrigerant | R22 |

| Freezing time | 7.4-74min |

| Infeed conveyor length | 1250mm |

| Belt width | 2000mm |

| Installed power | 20KW |

Notes: These parameters are subject to change based on different products and processes.

Recommended Applications Features- The mesh belt tunnel freezer is equipped with an efficient and hygienic evaporator that uses the latest liquid supply method to ensure the heat exchange efficiency is 20% higher than traditional processes.

- The mesh belt features a circular air duct with a vertical symmetry in order to enhance the heat exchange effect.

- The mesh belt tunnel freezer uses an imported cold storage insulated panel production line for the production of panels. This production line is energy efficient and features a high quality.

- The mesh belt tunnel freezer is equipped with an intelligent central control system, automatic detection device and warning lights, which makes it easy for users to operate and maintain.

- We can design and produce the mesh belt tunnel freezer according to different frozen food conditions and customer requests.

- The production capacity ranges between 200kg/h to 3000kg/h.

- The conveyor belt width ranges between 1500-3500mm.

- We make customized infeed and outfeed conveyor upon customers' requirements.

- Fully welded enclosure structure is optional.

- The CIP automatic cleaning system can be chosen to efficiently clean the interior of the freezer, and reduce downtime.

Founded in 1986, Square Technology Group Co. is a dedicated manufacturer engaged in the development, production, and sales of cold chain systems. We provide customers with outstanding refrigeration solutions and quick-freezing food processing systems for those handling agricultural products, seafood, baked goods, and pre-prepared foods. Through more than three decades of development, we have established long-term cooperative relationships with a number of leading food producers, including QL Group, Read Chamber, Morpol, Tyson, CP, Hormel, Cargill, Tingyi, Sunner, Zhouheiya,Juewei, and Anjoy.

Inquiry Form

Square Technology Group Co.,Ltd.

Add.: 3888 Jintong Highway, Nantong City, Jiangsu Province

Postcode: 226371

Contact: Fiona Tao, Vivi Wu

Tel.: +86-513-86615866

Fax: +86-513-86221280-8016