- Home

- Products

- Industry Freezer

- Spiral Freezer

- Self Stacking Spiral Freezer

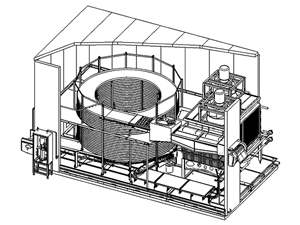

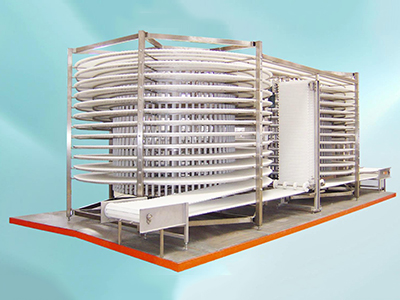

Self Stacking Spiral Freezer

The self-stacking spiral freezer produced by Square Technology applies to individual quick frozen of granulated and blocked food, such as the hot-pot spices, meatballs, hamburger cakes, fried chicken nuggets, fish and other cooked food and small-package food. The self-stacking spiral freezer is fed from a low point and discharges from a high position, which can be paired with your front and rear processing lines, and it is easy to use.

Parameters| Items | Parameters |

| Model | STF7624 |

| Layout Dimension | 8902×4798×4585mm |

| Freezing products | 150g chicken drumsticks |

| Output | 1.5 T/h |

| Infeed temperature | +15℃ |

| Outfeed temperature | -18℃ |

| Refrigeration consumption | 200 kw |

| Refrigerant | R717 |

| Freezing time | 22.5-90 min |

| Mesh belt layers | 24 layers |

| Total mesh belt width | 760 mm |

| Mesh belt effective width | 715 mm |

| Layer pitch | 80 m |

| Allowed product height (max.) | 65 mm |

| Belt length per layer | 13.1 m |

| Belt area per layer | 7.7 ㎡ |

| Installed power | 46 kw |

Notes:The above parameters are set based on freezing of 1.5T chicken drumsticks (150 g) per hour. These parameters are subject to change according to different products and freezing requirements.

Recommended Applications- The evaporator of the self-stacking spiral freezer is made of aluminum alloy and stainless steel. It features a finned design, which is optimal for preventing the growth of bacteria. The reasonable arrangement of the evaporation pipes, high flange and vari able fin pitch design can make the airflow of the device smooth while running, and is not easy to frost.

- The self-stacking spiral freezer can be equipped with a centrifugal fan, the windward area of which is large, and the freezing distance is short, making a perfect freezing effect. The cells of the frozen food are less-damaged, and the water loss is lower after defrosting, which ensures the taste of the food remains unchanged.

- The spiral freezer is equipped with an intelligent central control system, automatic detection and alarm light device, which is convenient for users to operate and maintain.

- The compact and efficient internal design of the freezing equipment minimizes the space required for maximum freezing capacity.

- The self-stacking spiral freezer needs minimal support, which saves material usage, reduces bacteria, and facilitates customer maintenance and cleaning.

- It is equipped with a CIP automatic cleaning system, which can be used to clean and disinfect the interior of the freezer, making the equipment meets the hygienic requirements of safe foodstuffs.

- We can design and manufacture the non-standard product according to different conditions of the frozen food and customer requests.

- The production capacity is from 1T/h to 6T/h.

- The mesh belt width is available for 660mm, 760mm, and 1060mm.

- The number of mesh belt layers is optional from 24 to 40 layers.

Square Technology Group Co.,Ltd.

Add.: 3888 Jintong Highway, Nantong City, Jiangsu Province

Postcode: 226371

Contact: Fiona Tao, Vivi Wu

Tel.: +86-513-86615866

Fax: +86-513-86221280-8016