- Home

- Products

- Industry Freezer

- Tunnel Freezer

- Fluidized Bed Freezer

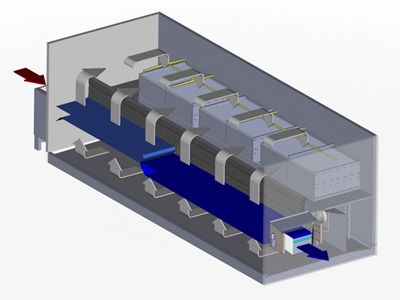

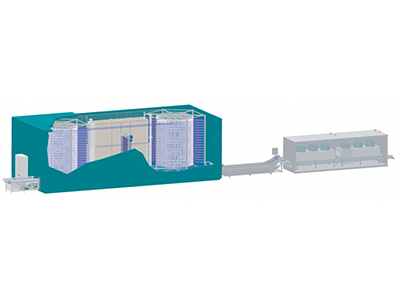

Fluidized Bed Freezer

The fluidized bed freezer is used to carry out individual quick freezing of small foods, such as soft, squishy, sticky fruits and vegetables and seafood. The fluidized bed freezer is capable of freezing a variety of vegetables, fruits, shells, fish, shrimp, meat products, dairy products, cooked food and more.

Recommended Applications Parameters| Items | Parameters |

| Model | FBF-NA50RS01 |

| Dimension | 9180×5060×4900mm |

| Frozen products | Pea |

| Output | 5000 kg/h |

| Feed temperature | +15℃ |

| Discharge temperature | -18℃ |

| Energy consumption | 650KW |

| Refrigerant | R22 or other refrigerants |

| Freezing time | 5-30min |

| Effective width of mesh belt | 1250mm |

| Fan | 6×18.5 KW |

| Installed power | 115KW |

Notes: The above parameters are set based on freezing of 5T peas per hour. These parameters are subject to change based on different products and processes.

Features- The fluidized bed freezer is equipped with a frequency converted regulating speed ventilator, adjustable air duct and porous conveyor belt, in order to ensure that different frozen foods from a stable and controllable fluid bed for the best freezing effect.

- The full fluidized freezer is equipped with a rotary agitator, which can effectively stop the high-moisture, high-viscosity food from crowding or massing into a cluster and freezing.

- The anti-icing system effectively prevents the freezing equipment stalling and damage caused by too much ice.

- The porous conveyor belt uses a particular tapered air-vent design and is paired with conveyor belt cleaning equipment. This effectively avoids air vent clogging, ensuring the device runs smoothly for long periods of time.

- The ADF air defrost system ensures continuous and efficient heat exchange of the evaporator, allowing it to work continuously.

- The production capacity ranges between 1500kg/h and 12500kg/h (calculated as peas).

- The most suitable combination of configurations is available based on customer needs.

- Various infeed and outfeed conveyors are available according to customer requirements.

- The freezer body can be a fully welded configuration.

- The CIP automatic cleaning system can be chosen to efficiently clean the freezer interior.

Founded in 1986, Square Technology Group Co. is a dedicated manufacturer engaged in the development, production, and sales of cold chain systems. We provide customers with outstanding refrigeration solutions and quick-freezing food processing systems for those handling agricultural products, seafood, baked goods, and pre-prepared foods. Through more than three decades of development, we have established long-term cooperative relationships with a number of leading food producers, including QL Group, Read Chamber, Morpol, Tyson, CP, Hormel, Cargill, Tingyi, Sunner, Zhouheiya,Juewei, and Anjoy.

Inquiry Form

Square Technology Group Co.,Ltd.

Add.: 3888 Jintong Highway, Nantong City, Jiangsu Province

Postcode: 226371

Contact: Fiona Tao, Vivi Wu

Tel.: +86-513-86615866

Fax: +86-513-86221280-8016